Canal Bridges and Canal Aqueducts; crossing valleys and rivers

There are a wide variety of bridges and aqueducts on the canals made from materials varying from wood to masonry to cast iron. Some just link fields together, others span deep river valleys.

Canal Masonry and brick bridges

When canals were built they cut across estates, farmlands and existing roads. The canal company was required in the Acts of Parliament that authorised the canal to ensure that no one was inconvenienced. Hence large numbers of bridges were required, often doing no more than linking two fields. Most were simple brick or stone structures, however many have a simple architectural grace. Much grander structures were erected when country estates were crossed and the permission of the landowners had to be courted, as with the high masonry bridge on the Shropshire Union Canal.

Canal Timber and cast iron bridges

Wooden bridges were cheaper to build than masonry or brick bridges. They were used for footbridges at locks and sometimes for accommodation bridges. Cast iron bridges were used, especially around Birmingham. These bridges were built to a common elegant design in Black Country iron foundries.

Cast Iron bridges were also used to take the towpath over the redundant loops created when the North Oxford Canal was straightened and shortened in the early nineteenth century.

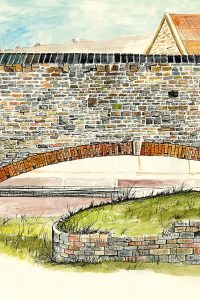

Canal Turnover or Roving bridges and split footbridges

Sometimes the towpath had to move from one side of the canal to the other. Turnover or roving bridges allowed the towing horse to cross the canal without the tow line getting caught up in the bridge. The smooth curves of these bridges often make them the most attractive structures, as the bridge on the Shropshire Union Canal on the left. Split bridges were used around locks to enable the towing line to pass through the bridge when the towpath did not go under the bridge.

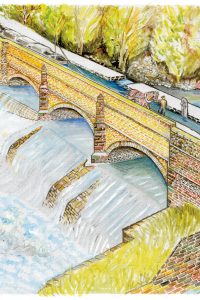

Canal Aqueducts

Aqueducts were not much liked by the early canal builders because the weight of the water and the clay needed to keep the canal trough watertight required a very substantial structure to support it. Masonry aqueducts like Hazlehurst Aqueduct on the Caldon Canal bear witness to this stature. Compare this with the Bearsley Aqueduct on the Stratford Canal or the Pontcysyllte Aqueduct on the Llangollen Canal which has a cast iron trough supported on tall slim masonry pillars. The cast iron contains the water and has sufficient rigidity without the great bulk of the masonry aqueduct.

Canal Swing and canal lift bridges

Movable bridges were usually cheaper to build than fixed bridges because they didn’t require the same heavy foundations and structure. Canals which were short of construction money often used lift bridges, as on the Oxford Canal and on the Llangollen Canal. Lift bridges were counter-weighted and usually operated manually or by using a windlass.

Swing bridges are common on a number of canals such as the Gloucester & Sharpness Canal where river craft did not have to lower their masts to pass and on the Leeds & Liverpool Canal where many have now been converted to electrical operation.

All materials and images © Canal Junction Ltd. Dalton House, 35 Chester St, Wrexham LL13 8AH. No unauthorised reproduction.

About

| Terms

| Privacy |

Returns |

Sitemap

| Contact Us

Web Hosting & Development

With over 800 pages, this website uses cookies to record visitor behaviour using Google Analytics. More information on Privacy Page. Page last updated: 09/10/2025.

Back to Menu....

Canal Heritage >>

Engineering >>